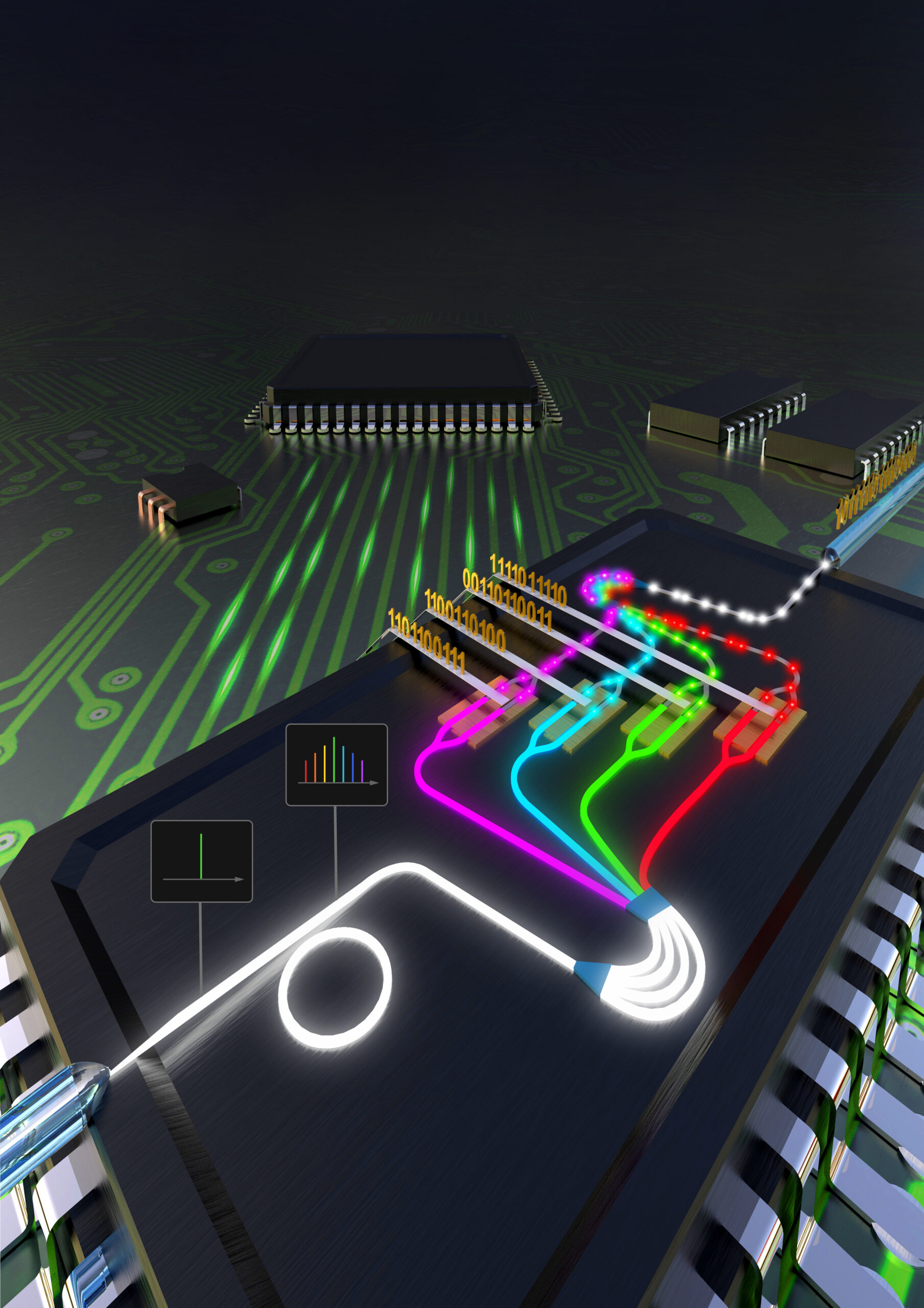

Platforms

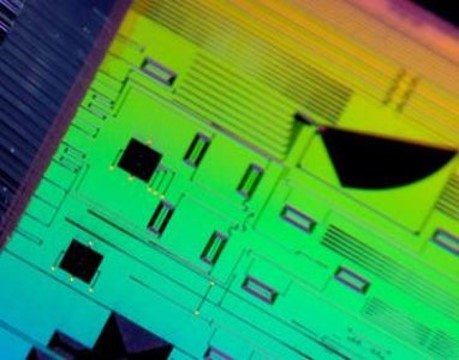

Design

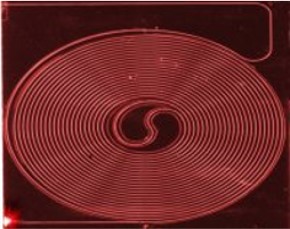

For both IMEC and LXI the PDKs runs in commercially available software (Synopsys, formerly known as PhoeniX Software, IPKISS). LXI already uses the PhoeniX Software which has full design capabilities from system level design to cross sectional design of the photonic waveguides in their current IR PDK. The PDKs contain standard building blocks, with validated performance, with which users can design their functional PIC. For building blocks which are not in the PDK the material properties of the stack are available for designers also to define new PIC building blocks.

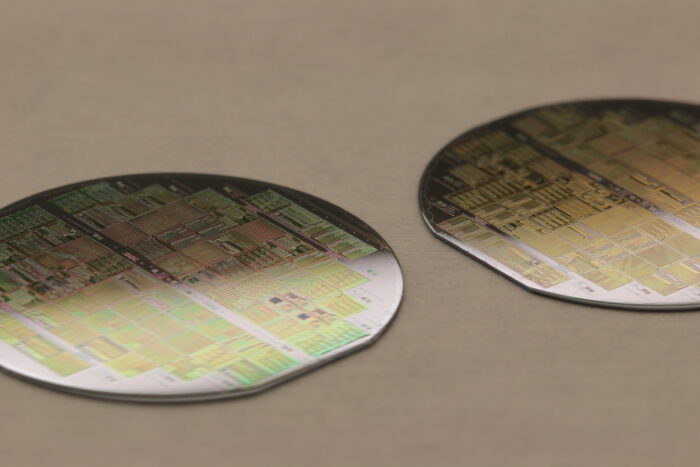

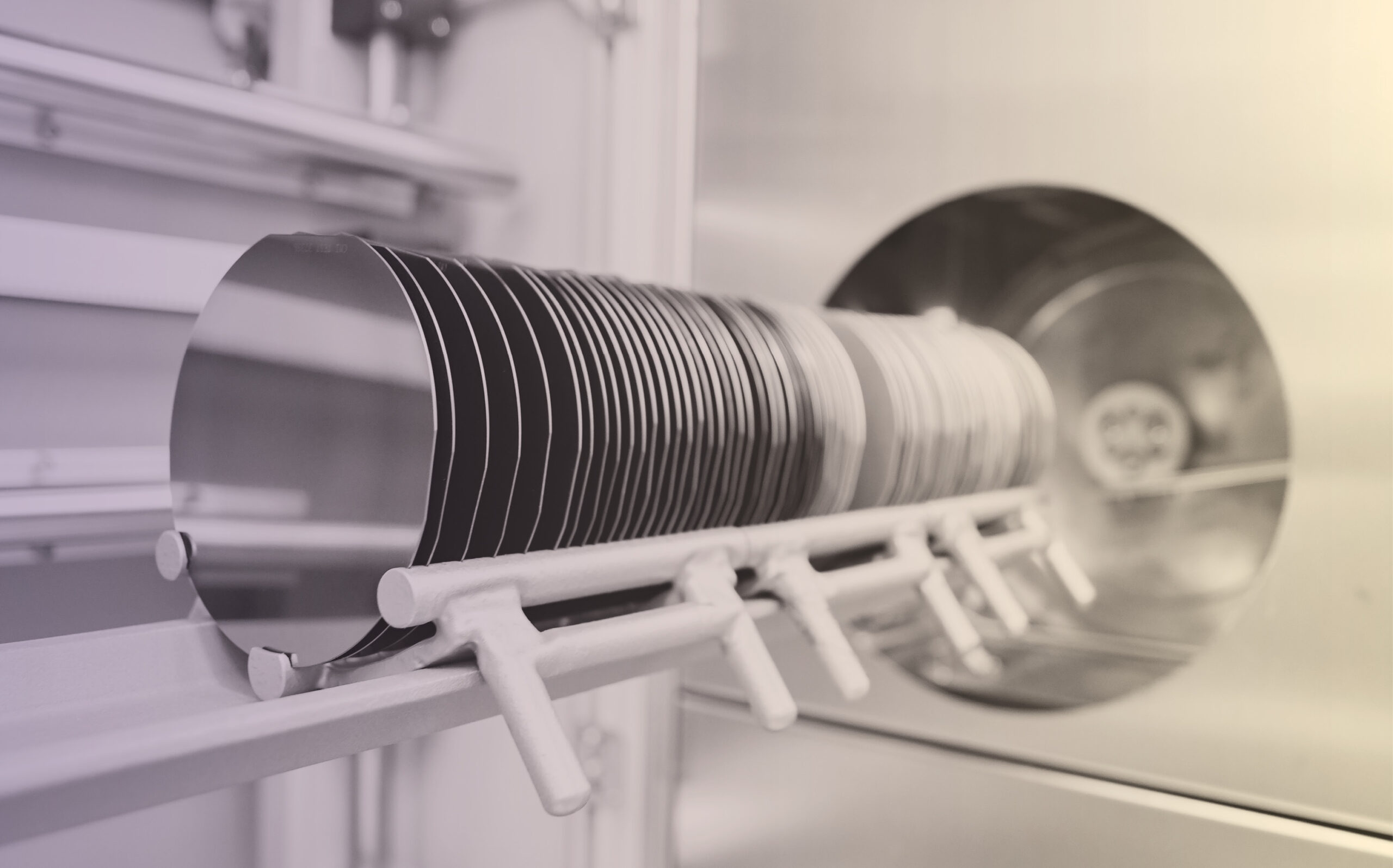

Prototyping

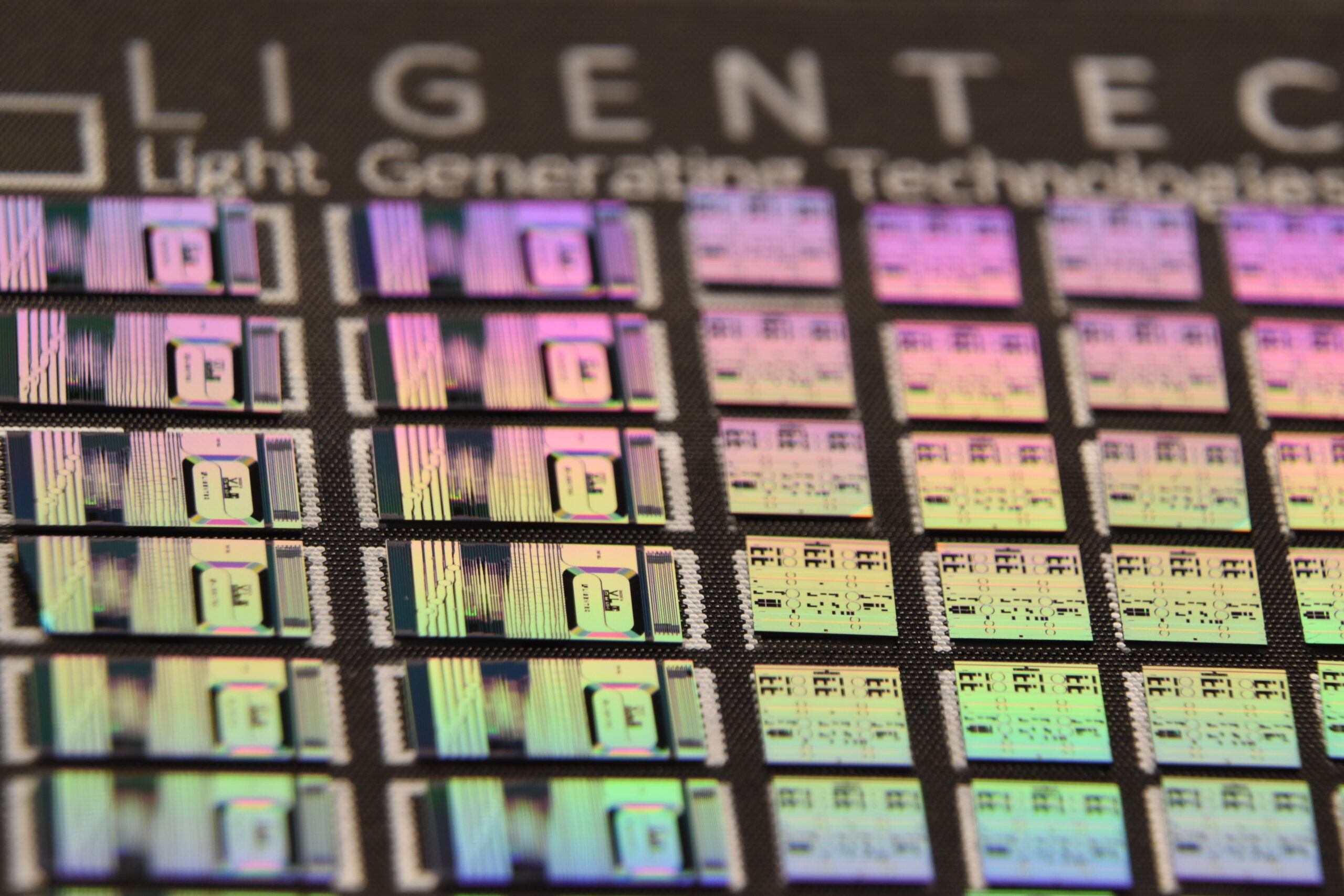

The manufacturing of the prototyping will be done in two different locations for the two SiN platforms involved. IMEC will use their 200 mm CMOS fab in which the SiN process is running as a fixed process. On wafer level this process is suitable for high volume processing. The small prototyping volume however is done via MPW wafer runs in order to keep the manufacturing cost of the PIC at an acceptable level. LXI runs the prototype runs of their SiN platform in the facilities in the Netherlands on 4 inch wafers, which also allows for cost effective prototype manufacturing. In addition to that the wafer space is also shared in this process via MPW runs. UPV-NTC will provide fast prototyping at chip level to prove new designs and concepts at low-cost production.

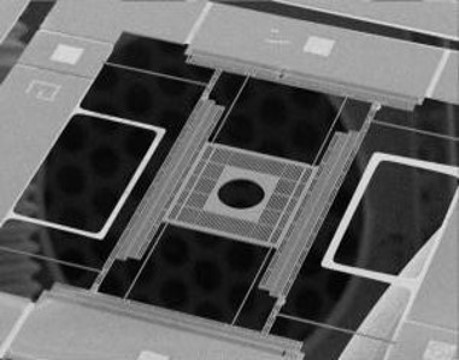

Measurement

The PIC devices that will be realized in the MPW engineering runs will be measured by measuring the performance of the individual building blocks. Each MPW run contains a set of test structures which will be measured by the foundries in order to validate that the process ran according to specification. The dedicated measurements on the functional designs of the full PIC will in this TP be done via the partners like TNO and ICCS, who have the test and measurement equipment for the full system measurements.

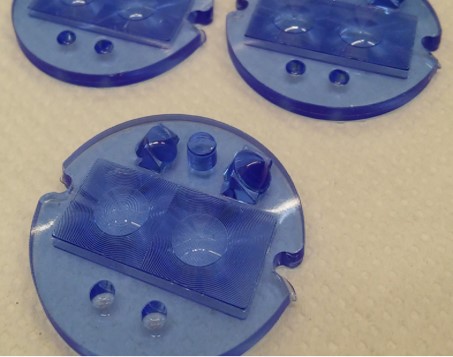

Packaging

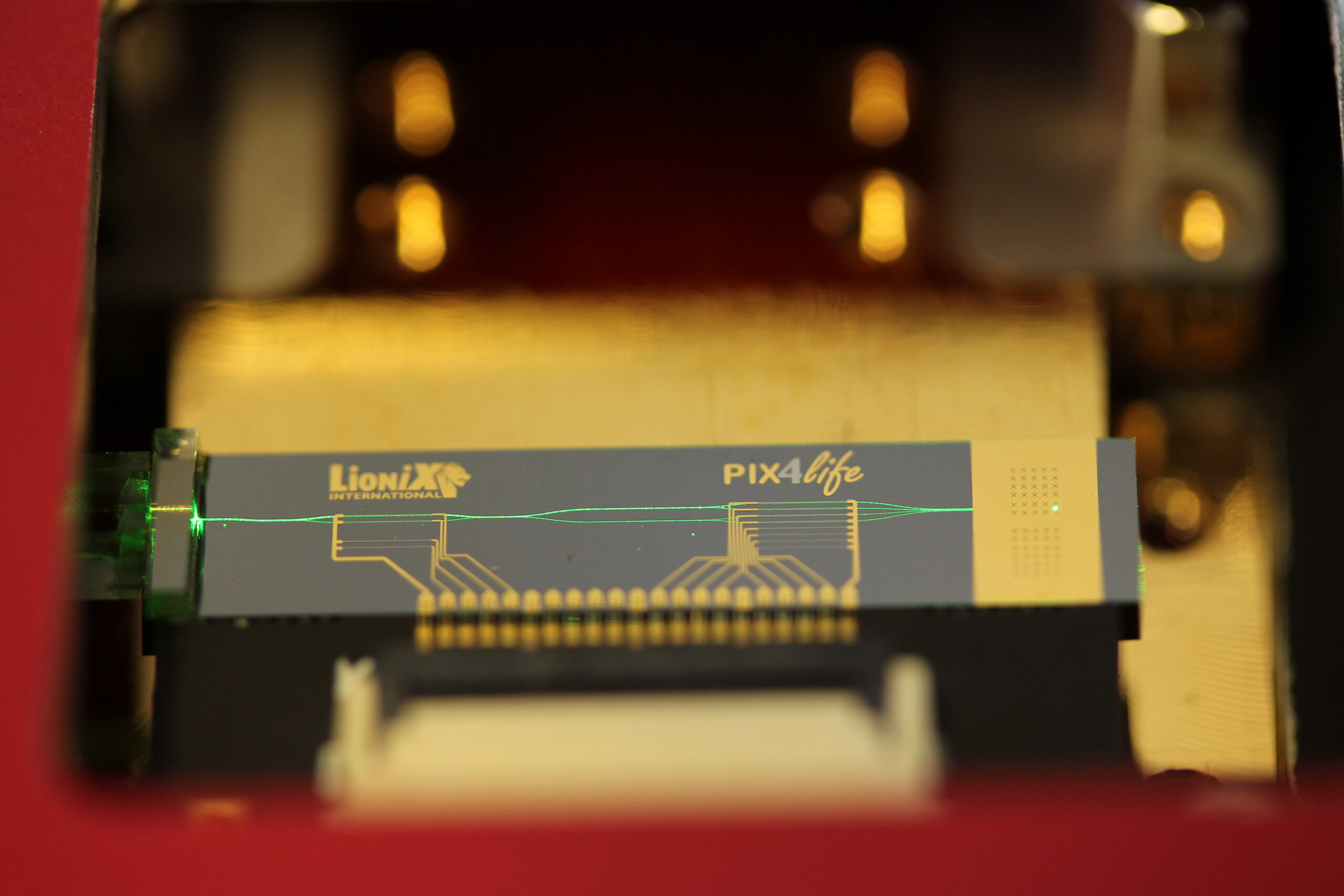

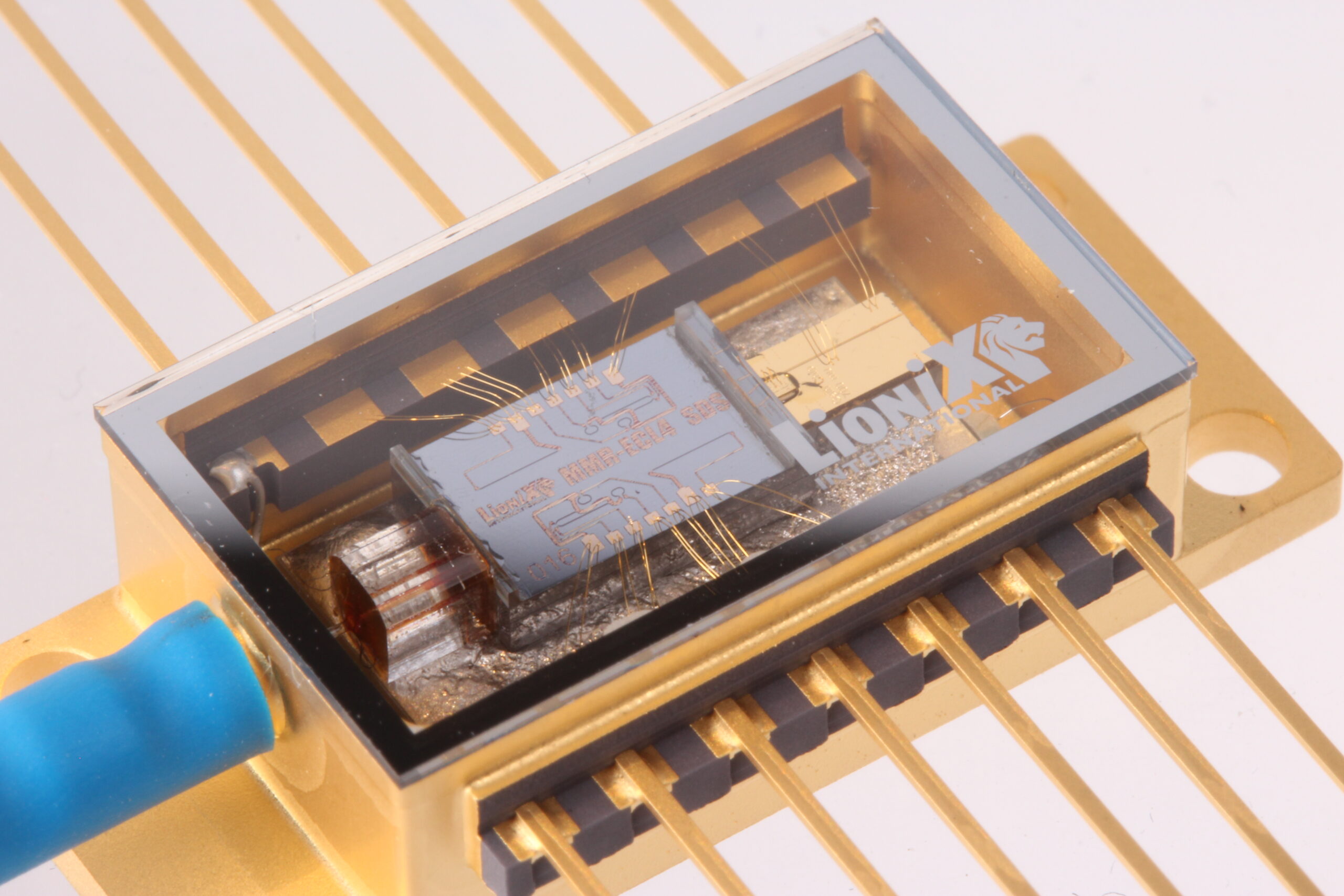

Packaging of SiN waveguides is something which LXI does for their customers as a vertically integrated company. For the MPW runs there are characterization packages available in which the MPW chips can be packaged in a standard manner. The moment the total assembly becomes a more exotic assembly of different components including lenses etc. a project partner like Tyndall-UCC will play an important role in the overall assembly.

Proof-of-concept

Proof-of-concepts include PIC devices made in the MPW runs in the different platforms and assembled into prototype packages allowing users an easy accessible waveguide platform. TP7 also delivers these prototype packaging for the MPW run and collaborates with the packaging partner Tyndall-UCC in the project to deliver more complex assemblies.

Reliability testing

Reliability testing is most often the next step in the PIC development and the biggest influence on the reliability is the assembly of the devices. The PIC platforms itself are stable over time, temperature etc. For the first prototype packages therefore the reliability testing will not be very important. The moment the proof of concept demonstrator is done a dedicated package that will meet the requirements of the applications will have to be designed. From telecom there is a lot of experience with robust and reliable packaging and Tyndall-UCC will play an important role in that also.