Platforms

Design

Design of production chains with simulation of process steps that link laser-based processes with respect to data and process time. For each process, software packages are available to plan the processing of material or parts. This includes path planning for laser-based manufacturing processes that join, ablate or add material to produce parts. CAM tools allow the transfer from product models to production data. Design of product features is supported by modelling tools that simulate final functionality of required product features. Software for design of construction in mechanical, fluid-dynamics and optics is part of the basic tool set for the development of manufacturing equipment, lasers and laser optics.

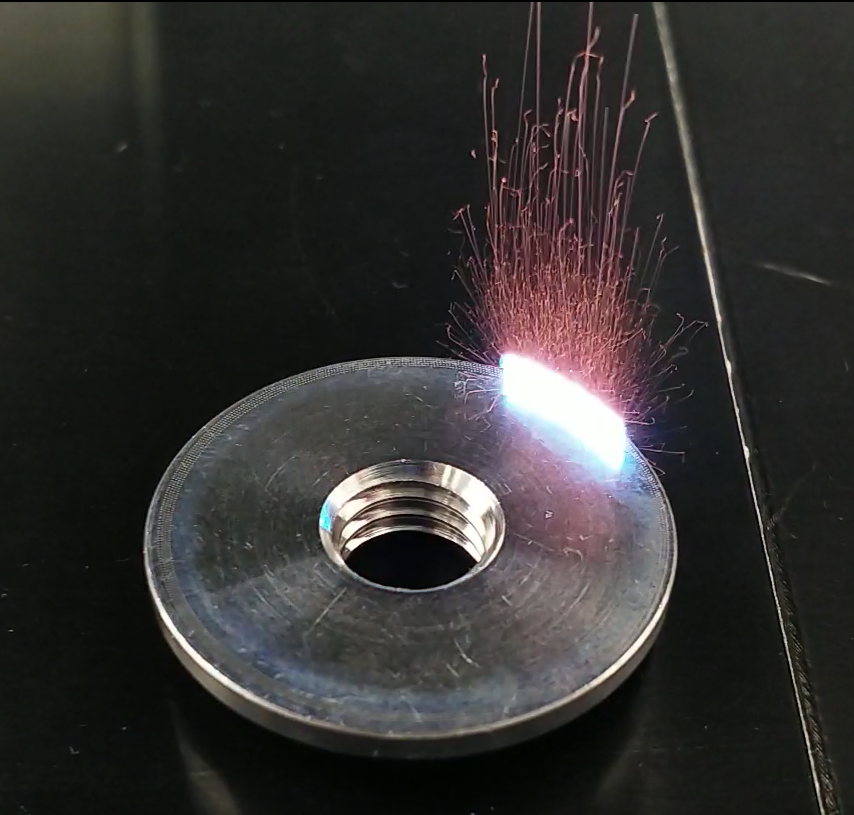

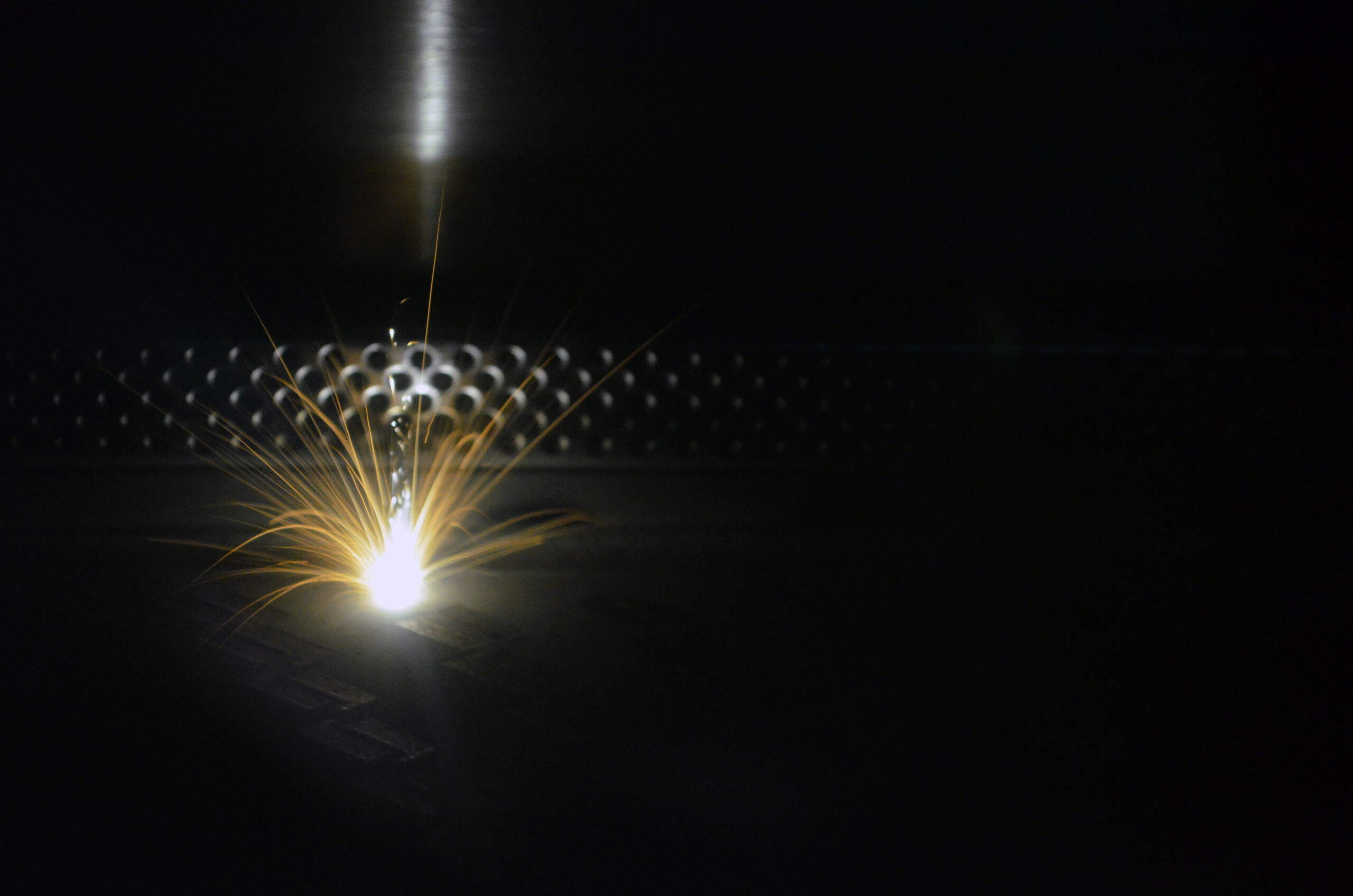

Prototyping

Facilities across Europe are joined together to offer all advanced laser-based manufacturing processes that are needed to facilitate the creation of prototypes. The technology platform offers equipment for a diverse range of industrial applications. There are machines for large scale welding including robot-based laser welding of industrial goods as well as machines for micro welding of medical products such as pacemakers or packaging of electronic devices. Ultrashort pulse (USP) lasers are available for testing ablation processes on specific materials and to develop processing strategies, also for USP based drilling in micro applications on sieves and foils as well as in macro applications for fan blades. Facilities on additively manufactured parts round off the prototyping on this platform.

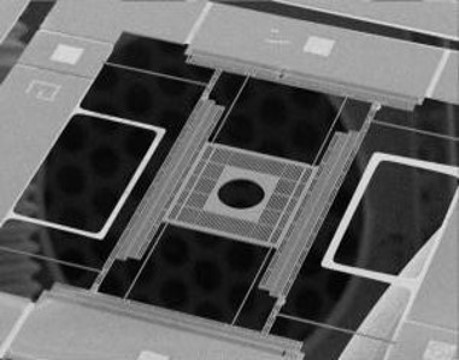

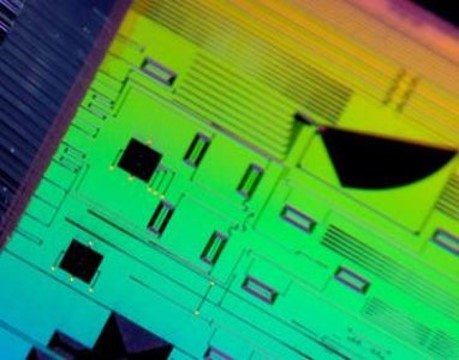

Measurement

Measurement technologies in the technology platform for laser-based manufacturing target part quality and process control. Interferometric measurement solutions are available for the detection of surface properties and geometries. In process control, dedicated instrumentation for spectrographic monitoring of process properties support machine vision analysis of products and parts. The application of specific sensors for quality control of the manufacturing processes is a key element at all supply chain facilities.

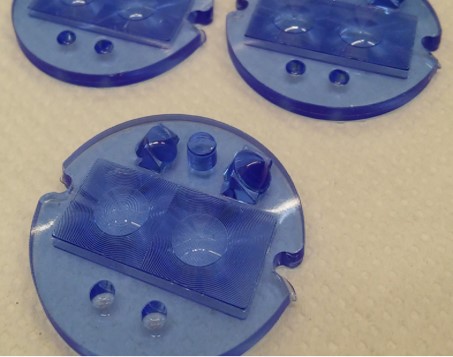

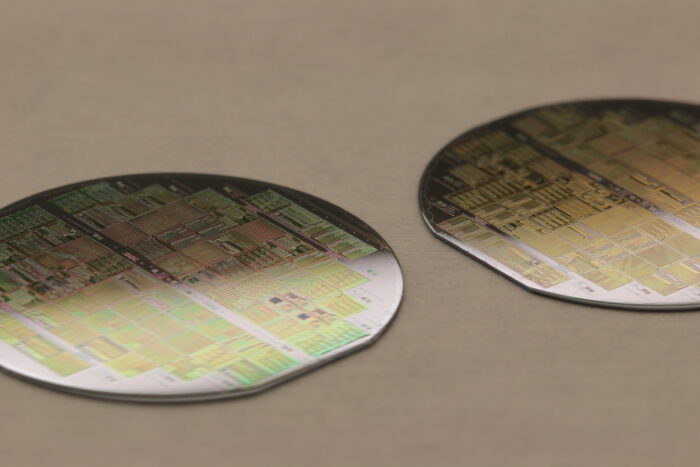

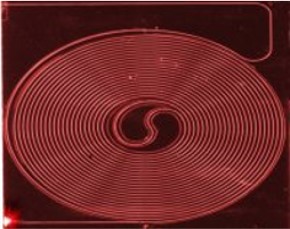

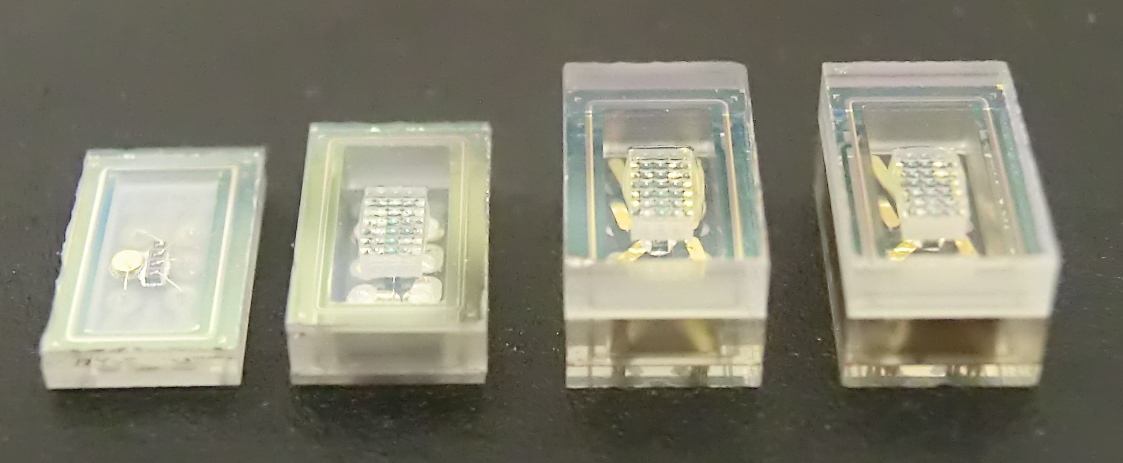

Packaging

Specific facilities offer packaging solutions for micro-electronics and fluidic application for medical, measurement and space sectors. Laser-based bonding of glass, glass brazing, laser-based additive manufacturing in combination with laser micro welding and other techniques are being used and developed in the test facilities. Adjacent technologies such as laser-based selective etching for ventilation holes and micro-fluidics, dot-welding of fibre mounts, light guide scribing for integrated spectrographic applications and lab-on-chip applications complement the packaging offering on this technology platform.

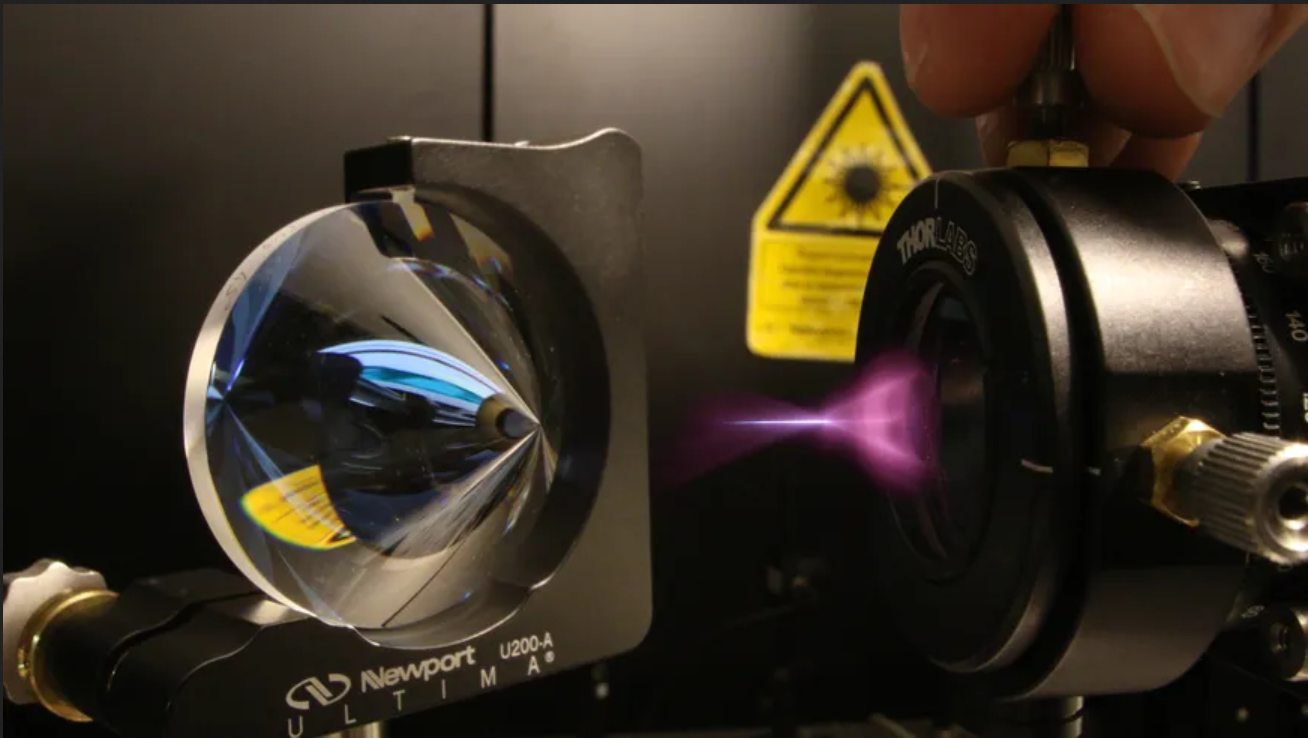

Proof-of-concept

All facilities have test beds for different levels of technical maturity. For early stage development, laboratories provide optical benches for a physical validation of optical designs with certified measuring tools or testing of damage thresholds of coatings with high power lasers. The feasibility of manufacturing equipment can be validated in production like environments, either in experiment set-up with pre-defined sample sizes or in application set-up with variability analyses. Products produced can be analysed with high level material analysis equipment and testing equipment to determine the fit of production results to specifications.

Reliability testing

Reliability testing is offered at laboratory level and in production like environments. In the labs, specific solutions can be assessed on test benches for performance and wear analysis. For validation of production challenges, all manufacturing equipment can be run at the competence centres under real production requirements. Software and infrastructure for data acquisition and data analysis offers the basis for condition and results tracking at selected installations. The results are used for quality analysis as an integral part of industrial requirements. These efforts result in recommendations for implementation of production ramp up and describe a path to certification.

Digital integration

Data acquisition and data analysis technologies are offered to enable the integration of production equipment and manufacturing processes into ICT environments. The facilities offer consulting in sensor integration and development of dedicated sensor solutions. Interfacing of new applications to existing installations is realised through individual software concepts, mostly based on open source solutions. Infrastructure for data lakes and the application of artificial intelligence is available to derive solid ICT concepts along the development of new manufacturing and product solutions.